Renewable fuels.

Europe: record of bio-methane production

In 2021 bio-methane production broke all records: now Europe has 1,023 production plants.

Holocaust Ukraine, energy emergency

On February 24th Putin started to invade Ukraine.

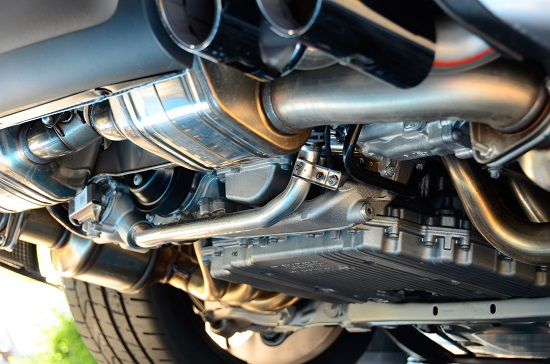

2035, stop to internal combustion engines?

During the fourth Cite’s meeting (the Inter Ministerial Committee for Ecological transition), chaired by Vice President and Minister of Ecological Transition Mr. Roberto Cingolani, the time frames for replacing vehicles with internal combustion engines have been defined.

Bio methane made from whiskey residues used by Glenfiddich’s fleet

Glenfiddich, the single malt Scottish whiskey most recognized in the world, launched a ‘closed loop’ sustainable transport initiative that will make it the first global spirits brand to manage the delivery fleet with green bio methane produced from the residues of its distillation process. Adopting a technology developed by the parent company William Grant & Sons, Glenfiddich distillery in Dufftown, in the north east of Scotland, transforms its production residues and waste in bio gas and then in bio methane called Ultra-Low Carbon Fuel (ULCF, a fuel with extremely low carbon emissions) with recognized qualities. Refueling stations have been installed in the distillery and the bio methane feeds specially set up trucks that deliver Glenfiddich whiskey. On the truck’s sides you can read Fueled by Glenfiddich - Transforming whiskey waste into ultra-low carbon fuel. The vehicles used by the whiskey producer are made by Iveco – in the pictures the natural gas fueled Stralis NP 460 – whose gas technology has been consolidated for some time.

From Eni and Basf the sustainable technology for producing bio propanol from industrial waste

Eni and the chemical company Basf signed a strategic agreement for a joint research and development initiative aimed at reducing the environmental impact of the transport sector. The cooperation aims to develop a new technology to produce advanced bio-propanol from glycerin resulting from the production of FAME (Fatty Acid Methyl Esters) bio diesel. The technology under development involves the conversion of glycerin into propanol through an innovative catalytic hydro treatment process and consists of a high pressure hydrogenation process using a BASF commercial catalyst, in order to produce high bio-propanol performance and purity, minimizing the production of by-products. The propanol obtained can be added directly as a bio component in the formulation of fuels. Thanks to the best chemical physical properties compared to conventional bio-ethanol and a high octane number, bio-propanol is a very valuable component in the formulation of premium gasoline and can potentially reduce greenhouse gas emissions by a percentage ranging from 65 and 75% compared to fossil fuels.

Environment changes are widespread and rapid, tragedy announced

Climate: bad news. According to the latest report of the Intergovernmental Panel on Climate Change (IPCC) published in August and approved by 195 governments, scientists detect changes everywhere on the planet. Many of these changes are unprecedented in thousands of years, and some of those that are already taking place – such as the continuous rise in sea level – won’t be reversible for hundreds or thousands of years. However, scientists point out, strong and steady reductions in carbon dioxide (CO2) and other greenhouse gas emissions could limit them, with rapid benefits for air quality, while to see global temperatures stabilize, it could take 20- 30 years.